Lead-acid batteries have been widely used in various fields due to their excellent performance in energy storage and conversion. Lead-acid battery is mainly composed of a battery tank, battery cover, and negative plate, dilute sulfuric acid electrolyte, separator and accessories. In this article, we will introduce the production technology of lead-acid batteries, which includes lead powder manufacturing, grid casting, plate manufacturing, plate forming, and battery assembly.

1.Introduction to Grid Casting

Grid casting is the process of making a grid, which is the carrier of the active material and also the conductive current collector. The quality of the grid is crucial to the performance of the battery. The ordinary open battery panels are typically cast with lead-antimony alloys, while maintenance-free battery grids are cast with low-antimony alloys or lead-calcium alloys. Sealed valve-regulated lead-acid battery grids are usually cast with lead-calcium alloys. The main control parameters of the grid are grid quality, grid thickness, grid integrity, and grid geometry.

2.Brief Introduction to Lead Powder Production

The lead powder is the raw material for making the plate. The lead powder is produced by the Shimadzu method or the Barton method. The quality of the lead powder is closely related to the quality of the lead products. The main components of lead powder are lead oxide and metallic lead. China uses the Shimadzu method to produce lead powder, while Europe and the United States use the Barton method. The result is that 1# electrolytic lead is processed into a lead powder that meets the requirements of the battery production process.

3.Introduction to Plate Production

The polar plate is the core component of the battery, and its quality directly affects various performance indicators of the battery. The main control parameters of the raw board are lead paste formula, apparent density, acid content, paste volume, degree, lead-free amount, and moisture content.

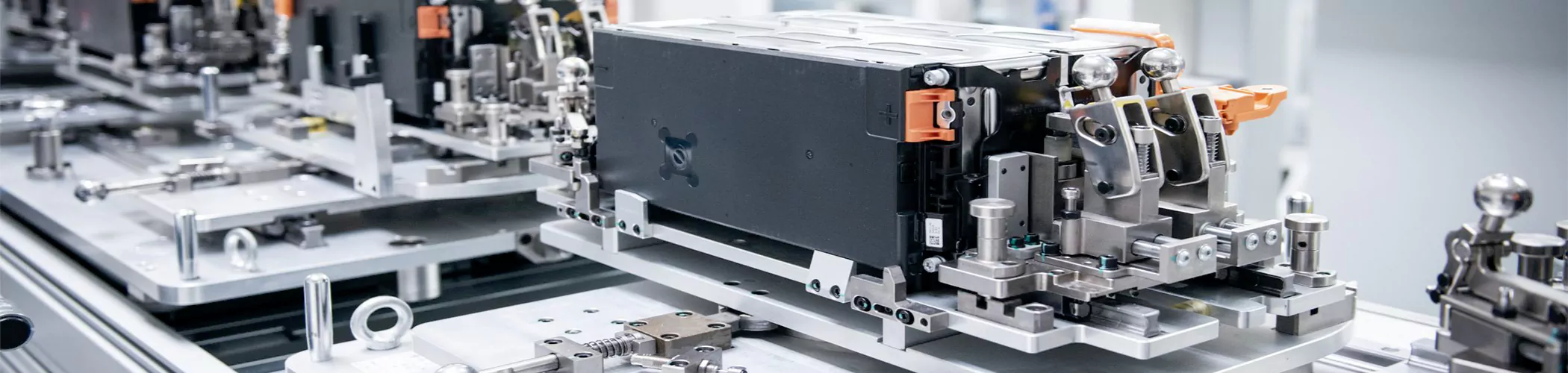

4.Introduction to Assembly Process

The assembly process is the process of assembling the grid and the plate into a battery. There is a big difference between the battery assembly of a car battery and a sealed valve-regulated lead-acid battery. Sealed VRLA batteries require AGM separators for tight assembly, while automotive batteries generally use PE, PVC or rubber separators. The main control parameters of battery assembly are welding quality and busbar material, sealing performance, positive and negative polarity, etc.

5.Introduction to Chemical Information

Plate forming and battery forming are two different battery manufacturing methods, which can be selected according to the specific situation. Plate formation is generally easier to control, but the cost is higher, and environmental pollution requires special treatment. Quality control of battery formation is difficult. Generally, the quality of the original plate produced is relatively high, but the cost is relatively low. The main control parameters of battery formation are tank acid content, tank acid density, tank acid temperature, power, and time.

The Bottom Line

The production technology of lead-acid batteries includes lead powder manufacturing, grid casting, plate manufacturing, plate forming, and battery assembly. The quality of each component directly affects the performance of the battery. Therefore, the production process of lead-acid batteries requires strict control of various parameters to ensure the quality of the battery.

Why choose us to buy batteries?

Vela Power Technology Co., Ltd. is a reputable VRLA battery supplier and manufacturer in China. The range of VRLA batteries includes AGM batteries, GEL batteries, OPzS batteries, and OPzV batteries. Compared with most other Chinese battery manufacturers, VELA Power can really supply customers with reliable batteries for various applications. Furthermore, we have a strong production capability to work together excellently with our customers, we welcome orders with the VELA brand; We are also flexible in accepting orders on an OEM basis. Contact us now! Your partnership with VELA will prove worthy of it.